Laser Engraving System ELS-02

Introduction

Laser technologies get more and more spread in material processing nowadays. Laser based manufacturing technologies for elements of micro- and nano-electronics take a special place among them.

In cooperation with LOTIS TII JV Ltd and Belarusian State University of Informatics and Radioelectronics, CS&IE Data Consulting took part in development of an industrial scale machine for engraving of 2D and 3D objects in transparent materials (e.g. glass).

Main implementation of this machine included the ability to form dotty 2D and 3D micro-objects by a pulse laser. Topological possibilities of such machines completely depend on the laser utilized, as well as on the processing software that includes a set of algorithms for concurrent control of laser and coordinate systems.

The system was designed for reproduction of 3D objects or 2D images prepared in 3D Studio MAX, AutoCAD, Adobe Photoshop or Corel PHOTO-PAINT, by creation of dotty defects in bulk transparent materials, such as optical glasses, crystals, or polymers.

Schematic view of Laser Engraving System ELS-02 is shown in Figure 1.

Figure 1: Laser Engraving System ELS-02

Specification

Detail information about Laser Engraving System ELS-02 can be found at LOTIS TII web site.

Here are some main parameters:

| Parameter | Value |

| Wavelengths, nm | 532 |

| Number of channels | 4 |

| Energy in channel, mJ | 1-10 |

| Max sample size, mm | 100x100x100 |

| Defect size, mm | 0.05-0.15 |

| Max production speed, points per seconds | 50 |

| Repeatability, mcm | ±10 |

| Max points quantity in one object | > 2000000 |

| Control Software | Windows 98/NT/2000 based |

| Size, mm | 1440x830x1250 |

| Weight, kg | 240 |

| Power requirements | Single phase 220+20 V, 50-60 Hz, 1500 W |

| Water requirements | No external water |

Laser Object Forming

NanoSculptor software was implemented to enable easy and user friendly control of full-scale laser engraving machine.

2D Objects

Preparation of 2D objects is realized by means of standard graphical software, e.g. Corel PHOTO-PAINT or Adobe PhotoShop, taking into consideration that prepared picture must be saved in standard, black-and-white bitmap file for Windows. Besides, the files can be prepared and then converted by system in STL binary size, as well as in CAD system size – the files with DXF extension.

3D Objects

3D objects are prepared in 3D Studio MAX software. Additional scripts are to be installed for successful objects conversion: “Divide Curves”, “Divide Meshes”, and “Export Data”. The scripts listed transform an object into layers, and after that coordinates of points are calculated for each level based on the distance between layers and points coordinates that form the object.

Features

NanoSculptor software is used to control the process of 3D and 2D images forming. Its implementation is based on Microsoft technologies, such as .NET, OLE, COM/DCOM, ActiveX, etc.

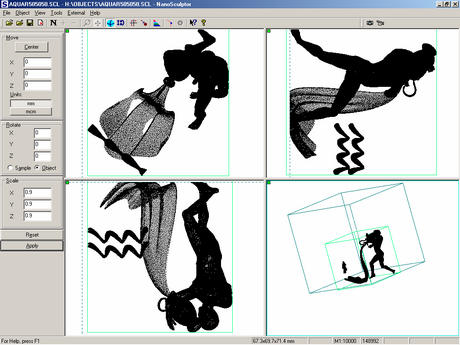

Screenshot of NanoSculptor software for 3D object forming is shown in Figure 2.

Figure 2: NanoSculptor software user interface

Modeled object in three surfaces (XY, XZ, and YZ) as well as the isometric image or the perspective view is presented on the computer screen. NanoSculptor has the following basic features that allow easy object adaptation for further processing:

- changing of size and location at any point of workpiece;

- pivot at any angle;

- optimized object centering;

- sorting of image points for minimization of processing time;

- converting the files created by various programs into a compatible format;

- storing the point of forced or emergency stop for the object in the non-volatile memory;

- controlling the defect formation;

- displaying the process of structure creation on PC screen.

NanoSculptor is connected to positional laser control system to enable laser engraving machine control.

Discretization Method

Main problem in discretization process is the number and coordinates of points representing the object. Three basic methods are used in NanoSculptor for these purposes:

- Discretization method of the object is based on division on sections.

- Discretization method is based on the algorithm of triangle filling by points.

- Discretization by means of parallel bunches.

The first and the second methods are implemented in 3D Studio MAX. The last one is specially implemented in NanoSculptor software.

Conclusion

Laser Engraving System ELS-02 has been developed for 3D objects forming, including NanoSculptor software. Features of full-scale laser engraving machine enable repetition workpieces as a demand for laser forming of 2D and 3D objects inside transparent materials. User friendly interface of NanoSculptor software enables very flexible control of objects forming process. NanoSculptor is deeply integrated with 3D Studio MAX software and is implemented using Microsoft technologies, such as .NET, OLE, COM/DCOM, ActiveX, etc. A combination of hardware and software solutions allows achieving high demands that are brought to the devices using laser bunch for the object forming in “micro” and “nano” scale.